Introduction

Kanban project management is a visual method for optimising workflow and enhancing productivity. This approach, rooted in Japanese manufacturing principles, has evolved into a powerful tool for various industries. Originating from Toyota’s production system in the 1940s, Kanban was adapted for software development in the early 2000s.

This article explores:

- The foundations and core principles of Kanban

- Key components of a Kanban system

- Implementation strategies for project management

- Benefits and metrics of Kanban

- Comparisons with other methodologies

- Best practices and common challenges.

By understanding Kanban’s versatile nature, teams can streamline their processes and achieve continuous improvement. Whether you’re new to Kanban or seeking to refine your existing practices, this comprehensive guide will provide valuable insights into mastering this efficient project management approach.

Foundations of Kanban

Origins in Toyota’s manufacturing system

The Kanban system originated in Toyota’s manufacturing plants during the late 1940s. Taiichi Ohno, an industrial engineer, developed this method to optimise production efficiency. The system was inspired by supermarket restocking practices, where items are replenished only when needed.

Adaptation to software development and other industries

In the early 2000s, software development teams began adopting Kanban principles. David J. Anderson pioneered this adaptation, applying Kanban to knowledge work. Since then, various industries have embraced Kanban for its versatility and effectiveness in managing workflows.

Core principles of Kanban

Kanban is built on six fundamental principles:

- Visualise the workflow: Create a visual representation of your work process using a Kanban board. This provides a clear overview of task progression and bottlenecks.

- Limit work in progress (WIP): Set maximum limits for tasks in each workflow stage. This prevents overloading and improves focus and efficiency.

- Manage flow: Monitor and optimise the smooth movement of work items through the system. Identify and address bottlenecks promptly.

- Make process policies explicit: Clearly define and communicate rules and guidelines for how work should progress through the system.

- Implement feedback loops: Establish regular review points to gather insights and make data-driven improvements to the workflow.

- Improve collaboratively: Encourage team members to work together in identifying and implementing process enhancements continually.

By adhering to these principles, teams can create a flexible and efficient workflow management system. Kanban’s adaptability allows for gradual improvements without disrupting existing processes, making it an attractive option for various organisations.

Key components of a Kanban system

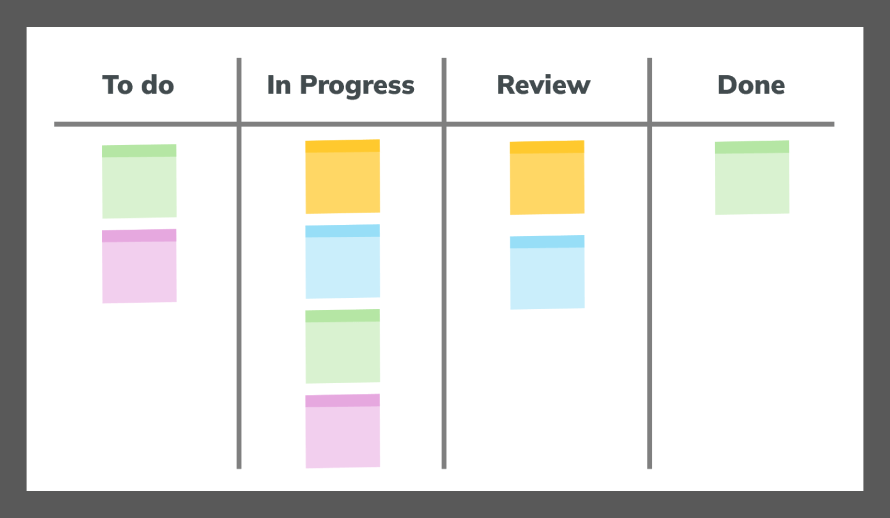

Kanban board

The Kanban board is the central element of any Kanban system. It provides a visual representation of your team’s workflow and task progress.

Physical vs digital boards

Teams can choose between physical and digital Kanban boards:

- Physical boards: Often use whiteboards or large wall spaces with sticky notes representing tasks.

- Digital boards: Utilise software platforms that offer virtual Kanban boards accessible from anywhere.

Both types have their merits, and the choice depends on team preferences and work environment.

Columns and workflow stages

Kanban boards are divided into columns representing different stages of work. A basic board might include:

- To Do

- In Progress

- Review

- Done.

Teams can customise these columns to reflect their specific workflow stages.

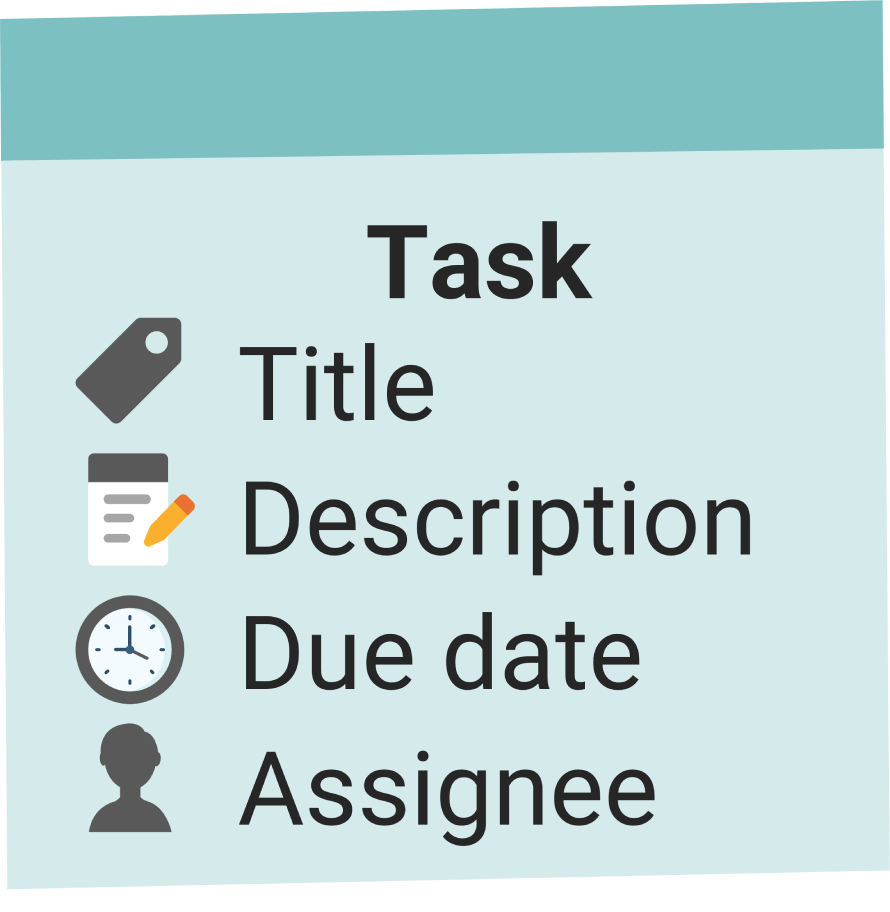

Kanban cards

Kanban cards represent individual work items or tasks on the board.

Purpose and information included

Each card typically contains:

- Task description

- Assignee

- Due date

- Priority level

- Additional relevant details.

This information helps team members quickly understand task requirements and status.

Movement through the workflow

As work progresses, team members move cards across the board’s columns. This visual movement allows for easy tracking of task progress and identification of bottlenecks.

Work in Progress (WIP) limits

WIP limits are crucial for maintaining an efficient workflow.

Definition and importance

WIP limits set the maximum number of tasks allowed in each workflow stage. They prevent overloading and encourage focus on completing current tasks before starting new ones.

Setting and adjusting WIP limits

To determine appropriate WIP limits:

- Start with a reasonable estimate based on team capacity.

- Monitor workflow and adjust limits as needed.

- Regularly review and optimise limits to improve efficiency.

Swimlanes and classes of service

Swimlanes and classes of service add another dimension to Kanban boards, enhancing organisation and prioritisation.

Purpose and implementation

Swimlanes are horizontal divisions on the board that can represent:

- Different projects

- Team members or departments

- Types of work

Classes of service categorise work items based on their urgency or impact:

- Expedite: Highest priority, bypass normal flow

- Fixed date: Time-sensitive items

- Standard: Regular work items

- Intangible: Low priority or improvement tasks.

Prioritisation and workflow management

Implementing swimlanes and classes of service helps teams:

- Visualise workload distribution

- Prioritise tasks effectively

- Manage different types of work simultaneously

- Ensure critical items receive appropriate attention.

By utilising these key components, teams can create a comprehensive Kanban system that promotes transparency, efficiency, and continuous improvement in their workflow management.

Implementing Kanban in project management

Getting started with Kanban

Implementing Kanban in project management begins with a thorough understanding of your current processes.

Mapping the current workflow

- Gather your team to discuss the existing workflow.

- Identify all stages a task goes through from inception to completion.

- Document these stages and their sequence.

This exercise provides a clear picture of how work currently flows through your team.

Identifying bottlenecks and inefficiencies

With your workflow mapped, analyse it for:

- Bottlenecks: Stages where work consistently piles up.

- Inefficiencies: Unnecessary steps or redundant processes.

- Delays: Points where work often stalls.

Identifying these issues helps prioritise areas for improvement in your Kanban implementation.

Creating a Kanban board

The Kanban board is the visual representation of your workflow.

Choosing the right tool (physical or digital)

Consider these factors when selecting between physical and digital boards:

| Physical Boards | Physical Boards Digital Boards |

| Tangible and visible | Accessible remotely |

| Easy to modify | Automated tracking |

| Limited space | Unlimited scalability |

| Team must be co-located | Supports distributed teams |

Choose the option that best suits your team’s needs and work environment.

Setting up columns and WIP limits

- Create columns representing each stage in your workflow.

- Add a ‘Done’ column to track completed work.

- Establish initial WIP limits for each column based on team capacity.

Remember, these limits can be adjusted as you learn more about your team’s workflow.

Developing team policies and guidelines

Clear policies ensure consistent use of the Kanban system across your team.

Definition of done

Establish criteria for when a task is considered complete. This might include:

- Code review completed

- Testing passed

- Documentation updated

- Stakeholder approval received.

Handling blockers and dependencies

Develop procedures for:

- Identifying and marking blocked tasks

- Escalating persistent blockers

- Managing dependencies between tasks or teams.

Clear guidelines help maintain smooth workflow and prevent stagnation.

Continuous improvement strategies

Kanban is not a set-it-and-forget-it system. Continuous improvement is key to its success.

Regular team meetings and reviews

Schedule recurring meetings such as:

- Daily stand-ups: Brief (15 minutes) daily updates on progress and blockers.

- Weekly reviews: Assess completed work and upcoming priorities.

- Monthly retrospectives: Evaluate the Kanban system’s effectiveness and identify areas for improvement.

These meetings foster collaboration and ensure the system evolves with your team’s needs.

Adjusting the system based on feedback and metrics

Regularly analyse key metrics such as:

- Cycle time

- Throughput

- Work in Progress (WIP).

Use these insights to make data-driven adjustments to your Kanban system. This might involve:

- Refining WIP limits

- Adjusting column structures

- Implementing new policies or guidelines.

By consistently reviewing and refining your Kanban implementation, you can create a highly effective and efficient project management system. Remember, the goal is continuous improvement, so be patient and open to change as you and your team learn and grow with Kanban.

Benefits of Kanban project management

Implementing Kanban in project management offers numerous advantages that can significantly enhance team performance and project outcomes.

Improved visibility and transparency

Kanban boards provide a clear, visual representation of work in progress. This transparency allows:

- Team members to quickly understand project status

- Managers to identify bottlenecks and resource allocation issues

- Stakeholders to track project progress without constant updates.

Enhanced team collaboration

The visual nature of Kanban fosters improved communication and teamwork:

- Team members can easily see who is working on what

- Cross-functional collaboration is encouraged as tasks move through different stages

- Shared understanding of project goals and priorities is facilitated.

Increased efficiency and productivity

Kanban’s focus on limiting work in progress leads to:

- Reduced multitasking and context switching

- Improved focus on completing tasks before starting new ones

- Streamlined workflows with fewer bottlenecks and delays.

Flexibility in planning and execution

Unlike rigid methodologies, Kanban offers adaptability:

- Changes can be implemented at any time without disrupting workflow

- Priorities can be adjusted easily by moving cards on the board

- The system evolves with the team’s needs and project requirements.

Reduced cycle times and faster delivery

By optimising workflow and reducing waste, Kanban can:

- Shorten the time from task initiation to completion

- Enable faster feedback loops and iterative improvements

- Facilitate quicker delivery of value to customers or stakeholders.

The benefits of Kanban extend beyond these key areas. Teams often report improved job satisfaction, reduced stress, and better-quality outputs. As organisations become more proficient with Kanban, they may see improvements in predictability, risk management, and overall project success rates.

Kanban metrics and analytics

Effective use of Kanban relies on data-driven decision-making. Key metrics and analytics tools help teams monitor performance and identify areas for improvement.

Cycle time

Cycle time measures the duration from when work begins on an item until it’s completed. This metric helps teams:

- Understand how long tasks typically take

- Identify process bottlenecks

- Set realistic expectations for task completion.

To calculate cycle time, track the time each task spends in the “In Progress” column.

Lead time

Lead time is the total time from when a task is requested to when it’s delivered. It includes both waiting time and cycle time. Lead time helps:

- Manage customer expectations

- Identify delays in starting work on new items

- Improve overall process efficiency.

Throughput

Throughput measures the number of items completed in a given time period. This metric provides insights into:

- Team productivity

- Capacity planning

- Identifying trends in work completion rates.

Track throughput weekly or monthly to gauge team performance over time.

Cumulative flow diagrams

Cumulative flow diagrams (CFDs) visually represent the status of tasks over time. They help teams:

- Identify bottlenecks and constraints

- Visualise work in progress (WIP) levels

- Understand how work flows through the system.

CFDs show the number of items in each workflow stage, with time on the x-axis and number of items on the y-axis.

Control charts

Control charts track cycle times for individual items and display them over time. They help teams:

- Identify outliers in task completion times

- Understand process stability

- Predict future performance.

Upper and lower control limits on these charts indicate expected cycle time ranges.

By regularly analysing these metrics, teams can gain valuable insights into their Kanban process. This data-driven approach enables continuous improvement and helps teams optimise their workflow for maximum efficiency and productivity.

Comparing Kanban to other project management methodologies

Understanding how Kanban differs from other methodologies can help teams choose the best approach for their needs.

Kanban vs Scrum

While both Kanban and Scrum are Agile methodologies, they have distinct differences:

| Aspect | Kanban | Scrum |

|---|---|---|

| Workflow | Continuous flow | Fixed-length sprints |

| Roles | Flexible | Defined (Scrum Master, Product Owner) |

| Changes | Allowed at any time | Discouraged during sprint |

| Planning | Continuous | Sprint-based |

| Metrics | Cycle time, Lead time | Velocity, Burndown charts |

Kanban offers more flexibility, while Scrum provides a structured framework with regular intervals.

Kanban vs traditional project management

Traditional project management, often associated with the Waterfall model, differs significantly from Kanban:

- Kanban focuses on continuous flow; traditional methods follow sequential phases

- Kanban allows for changes throughout; traditional methods resist mid-project changes

- Kanban emphasises visualisation; traditional methods rely more on documentation.

Hybrid approaches (e.g., Scrumban)

Recognising the strengths of different methodologies, some teams adopt hybrid approaches. Scrumban, for example, combines elements of Scrum and Kanban:

- Uses Scrum’s sprint structure with Kanban’s visual board

- Maintains Scrum roles but adopts Kanban’s focus on flow

- Allows for more flexibility in planning and execution than pure Scrum.

By understanding these comparisons, teams can select or adapt methodologies to best suit their project requirements and organisational culture.

Best practices for successful Kanban implementation

Implementing Kanban effectively requires adherence to certain best practices. These guidelines ensure a smooth transition and maximise the benefits of the Kanban system.

Start with the current process

Begin your Kanban journey by mapping your existing workflow:

- Analyse current procedures and identify all process steps

- Visualise the workflow on a Kanban board

- Avoid making immediate, drastic changes to established processes.

This approach minimises disruption and helps team members adapt gradually to the new system.

Encourage leadership at all levels

Successful Kanban implementation relies on distributed leadership:

- Empower team members to make decisions about their work

- Encourage proactive problem-solving at all levels

- Foster a culture of continuous improvement and innovation.

This approach enhances team engagement and promotes ownership of the Kanban process.

Focus on customer needs and expectations

Align your Kanban system with customer requirements:

- Identify and prioritise tasks that deliver value to customers

- Use customer feedback to inform process improvements

- Adjust WIP limits and workflow stages to meet customer demands.

By centring on customer needs, teams can ensure their efforts produce meaningful outcomes.

Balance demand against throughput

Maintain a sustainable workflow by managing incoming work:

- Monitor team capacity and adjust incoming work accordingly

- Use WIP limits to prevent overloading team members

- Regularly assess and optimise resource allocation.

This balance ensures consistent productivity without overwhelming the team.

Continuously review and improve the system

Embrace iterative improvement in your Kanban implementation:

- Schedule regular team reviews of the Kanban system

- Analyse metrics to identify areas for enhancement

- Encourage team members to suggest and implement improvements.

By fostering a culture of continuous improvement, teams can refine their Kanban system over time, leading to increased efficiency and effectiveness.

Common challenges and solutions in Kanban project management

While Kanban offers numerous benefits, teams may encounter challenges during implementation. Understanding these obstacles and their solutions can help ensure a successful adoption.

Resistance to change

Challenge: Team members may resist adopting new workflows and practices.

Solution:

- Educate the team on Kanban’s benefits

- Implement changes gradually

- Celebrate early successes to build momentum.

Incorrect WIP limits

Challenge: Improper Work-in-Progress (WIP) limits can lead to inefficiencies.

Solution:

- Start with conservative limits

- Monitor workflow and adjust limits based on data

- Encourage team input on setting appropriate limits.

Lack of team buy-in

Challenge: Without full team commitment, Kanban implementation may falter.

Solution:

- Involve the team in the implementation process

- Address concerns and questions openly

- Demonstrate how Kanban addresses existing pain points.

Inconsistent use of the Kanban board

Challenge: Irregular updates can render the Kanban board ineffective.

Solution:

- Establish clear guidelines for board usage

- Integrate board updates into daily routines

- Use automation tools to simplify updates.

Difficulty in measuring and improving flow

Challenge: Teams may struggle to quantify and enhance workflow efficiency.

Solution:

- Implement key metrics like cycle time and throughput

- Use visual analytics tools like cumulative flow diagrams

- Conduct regular retrospectives to identify improvement areas.

By anticipating these challenges and applying targeted solutions, teams can overcome obstacles in their Kanban journey and realise the full potential of this project management approach.

Conclusion

Kanban project management offers a powerful approach to optimising workflow and enhancing productivity. Its core principles of visualisation, WIP limits, and continuous improvement provide a flexible framework for teams across various industries.

Key benefits of Kanban include:

- Improved visibility and transparency

- Enhanced team collaboration

- Increased efficiency and adaptability.

As organisations continue to seek agile methodologies, Kanban’s future in project management appears promising. Its versatility and focus on incremental improvements align well with evolving business needs.

For teams considering Kanban, remember that successful implementation requires commitment and patience. Start by mapping your current process, gradually introduce Kanban principles, and consistently refine your approach based on data and team feedback.

By embracing Kanban’s principles and best practices, teams can create a more efficient, responsive, and collaborative work environment. The journey towards improved project management begins with a single step – why not make that step today?

FAQs

What is the main difference between Kanban and Scrum?

The primary distinction lies in their approach to work management. Kanban focuses on continuous flow and limiting work in progress, while Scrum operates in fixed-length sprints with defined roles and ceremonies.

How do I choose the right WIP limits for my team?

Start with a conservative estimate based on your team’s capacity. Monitor workflow and adjust limits as needed. Aim for a balance that prevents bottlenecks without causing idle time.

Can Kanban be used for non-software development projects?

Absolutely. Kanban’s principles are versatile and can be applied to various industries, including marketing, healthcare, and manufacturing. The key is adapting the system to your specific workflow.

What are the essential metrics to track in a Kanban system?

Key metrics include:

- Cycle Time

- Lead Time

- Throughput

- Work in Progress (WIP)

- Cumulative Flow.

These metrics provide insights into efficiency, productivity, and areas for improvement.

How often should we review and adjust our Kanban board?

Conduct daily stand-ups for quick updates. Hold weekly reviews to assess completed work and upcoming priorities. Perform monthly retrospectives to evaluate the system’s effectiveness and make adjustments.

Is it necessary to use specialised software for Kanban project management?

While specialised software can enhance visualisation and data analysis, it’s not mandatory. Physical boards with sticky notes can be effective for co-located teams. Digital tools become more valuable for remote teams or complex projects.

How can I convince my team to adopt Kanban methodology?

Highlight Kanban’s benefits, such as improved visibility and flexibility. Start with a small pilot project to demonstrate its effectiveness. Address concerns openly and involve the team in the implementation process.

What are the potential drawbacks of using Kanban?

Potential challenges include:

- Resistance to change

- Difficulty in setting appropriate WIP limits

- Lack of timeboxing, which some teams find motivating

- Potential for work to stagnate without proper management.

Can Kanban be scaled for large projects or organisations?

Yes, Kanban can be scaled using techniques like Portfolio Kanban or the Flight Levels approach. These methods apply Kanban principles across multiple teams or organisational levels.

How does Kanban support continuous improvement in project management?

Kanban promotes continuous improvement through:

- Visualisation of workflow bottlenecks

- Regular review meetings

- Metrics-driven decision making

- Encouragement of incremental changes.

This focus on ongoing refinement helps teams consistently enhance their processes and productivity.